Working With Top Brands

Explore Our Product Range (OEM/ODM)

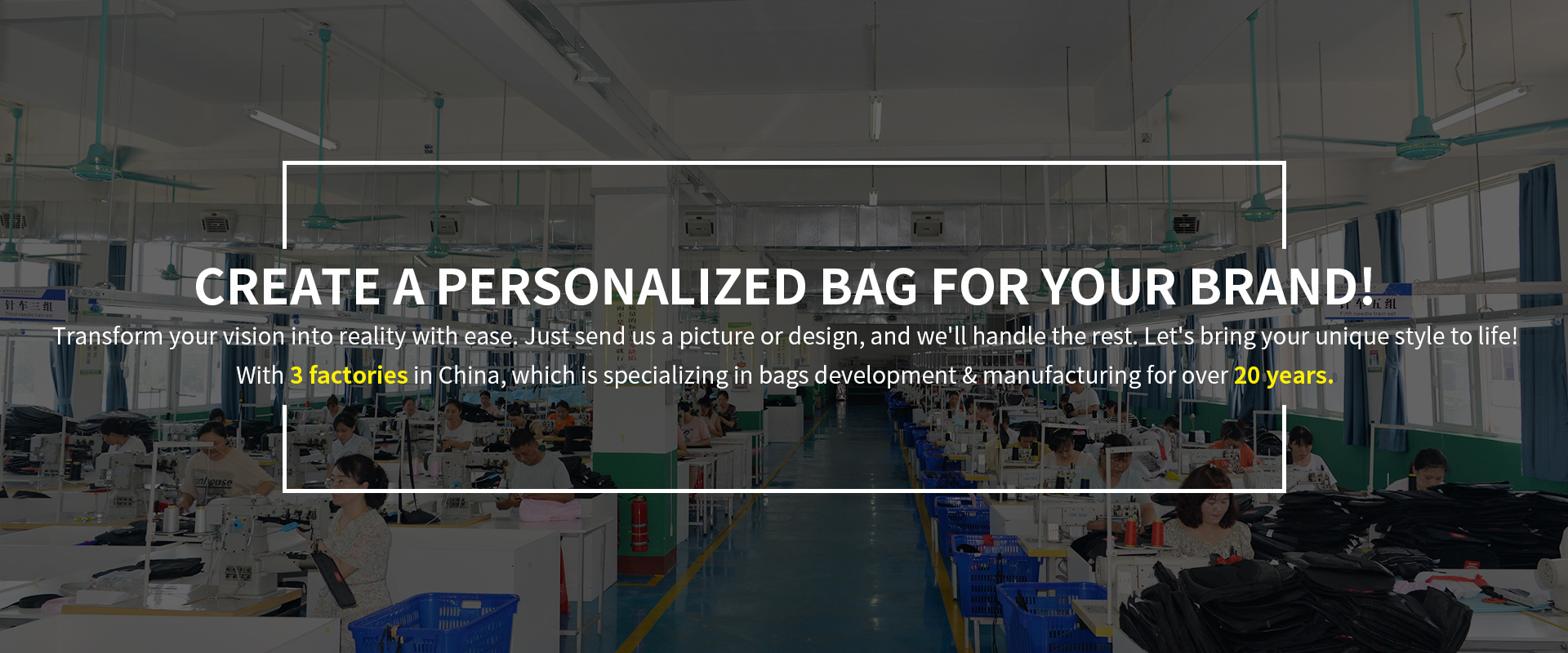

Personalize your handbag,Let us bring your unique style to life

Production Process

Personalize your handbag,Let us bring your unique style to life

01 Initial Material Inspection

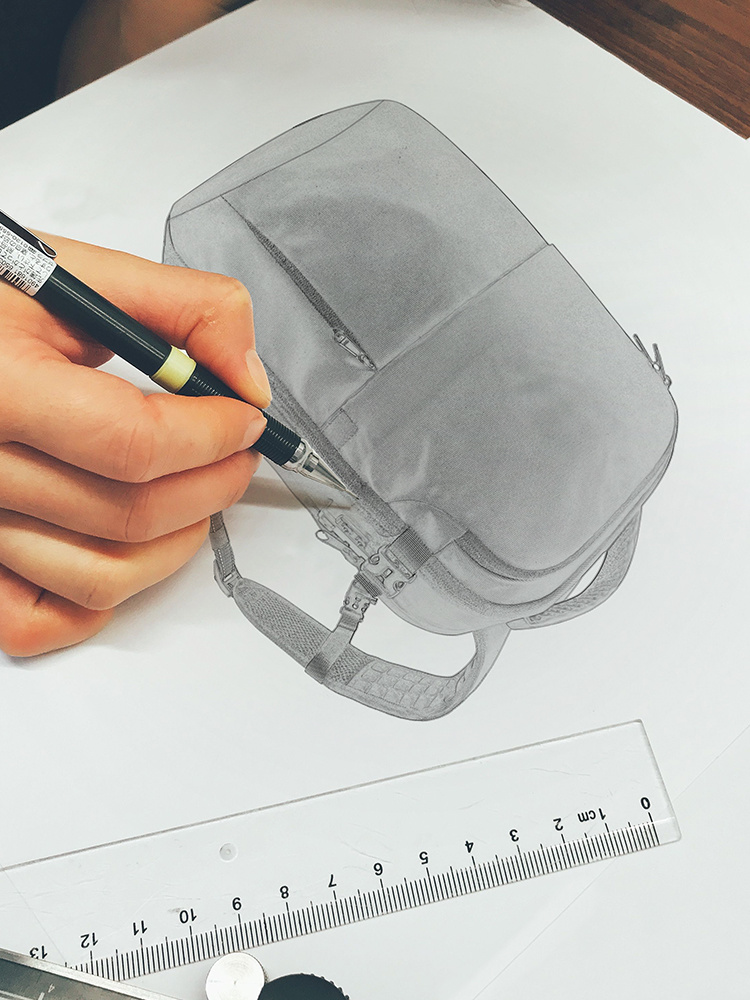

02 Design

03 Sampling & Proofing

04 Pattern Making & Cutting

05 Sewing & Assembly

06 Final Inspection

07 Packing & Labeling

08 Warehousing & Inventory Management

01

Initial Material Inspection

Material Quality Assessment: Conduct a meticulous inspection of incoming materials, including fabrics, zippers, and buckles, to check for quality, color consistency, and potential defects. This ensures only premium materials advance to production.

02

Design

03

Sampling & Proofing

Prototype Creation: Create sample bags based on design specifications, allowing designers to evaluate functionality, aesthetics, and construction quality. Testing & Feedback: Assess the prototype for design flaws or improvement areas and implement adjustments accordingly.

04

Pattern Making & Cutting

Pattern Development: Generate precise patterns for each component of the bag, which will guide fabric and material cutting. Material Cutting: Accurately cut materials according to patterns, ensuring all pieces align seamlessly for the assembly process.

05

Sewing & Assembly

Industrial Assembly Sewing: Stitch together cut pieces using industrial machines, adding elements like zippers, straps, and linings as specified. Quality Control: Regularly check stitching for consistency and strength, ensuring durability and adherence to quality standards.

06

Final Inspection

Quality Assurance: Conduct a comprehensive inspection of finished bags, reviewing stitching, construction, and overall appearance for any defects. Functionality Testing: Confirm that zippers, pockets, and straps function smoothly and meet design expectations.

07

Packing & Labeling

Protective Packaging: Secure each bag with protective materials (plastic bags, bubble wrap, or custom-designed boxes) to prevent damage during transit. Product Labeling: Attach labels and tags with product details, barcodes, and branding information.

08

Warehousing & Inventory Management

Organized Storage: Arrange packed bags systematically in the warehouse according to inventory protocols for efficient tracking and retrieval. Inventory Oversight: Maintain accurate records of stock levels and shipment movements to ensure optimal space utilization and streamlined inventory management.

Dongguan Letong handbags co.,ltd

Letong Backpacks, founded in 2000, is dedicated to providing best-in-class service and expertise in designing, developing, and manufacturing high-quality bags. Our mission is to deliver well-made, thoughtfully designed products while ensuring well-executed orders that help our clients succeed in the market with quality and sustainable solutions.

From design and conception to production and logistics, Letong understands the business from the inside out and adapts to the fast-changing environment. Our headquarters and production base are located in Dongguan City, covering an area of 4,000 square meters and employing over 500 staff. We also have established factories in Xiamen and Vietnam.

Founded in

Factory Area

Number of employees

What Our Customers Say

Uncompromising quality meets personalized style in our custom-designed bags, making a statement wherever you go

Blog